Available with LSZH or other jacket for

flame retardant or any other features

Available with special Design according to

the customer request Delivery length

upon customer request Other color coding

is available according to the customer request

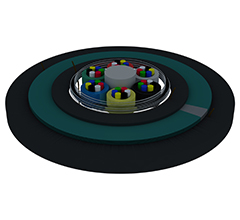

CONSTRUCTION:

|

Specification |

Recommended |

|||

|

Standard |

IEC 794-1, ITU-T G652D, ITU-T G655 |

|||

|

Construction |

||||

|

Design Type |

1-layer cable core /filling jelly/steel tape as armor/2jackets |

|||

|

Number of Fiber |

4 ... 144 |

|||

|

Optical Fiber |

Type |

Single Mode LWP- NZDSF |

||

|

Color |

1)white 2) red 3) Green 4) blue5) yellow6) black 7) brown 8) violet 9) orange 10) pink 11) gray 12) natural |

|||

|

Central strength Member |

Material |

FRP |

||

|

Diameter |

Nom. 2.5 mm that will up coat to suitable diameter if required |

|||

|

Loose Tube

|

Tube Material |

PBT |

||

|

Filling Compound |

Thixotropic jelly compound |

|||

|

Assembly |

6 optical fibers will have placed loosely into a jelly-filled thermoplastic tube |

|||

|

Diameter |

Nom. 2.4 mm |

|||

|

Number of Fibers |

6 or 12 |

|||

|

Color |

|

1)white 2) red 3) Green 4) blue5) yellow6) black 7) brown 8) violet 9) orange 10) pink 11) gray 12) natural |

||

|

Stranding |

6…12 loose tubes (and if necessary fillers) will be stranded around the strength member and will wrapped with a layer of polyester tape |

|||

|

Core Wrapping |

Polyester tape |

|||

|

Inner Sheath (Optional) |

Material |

Polyethylene colored black |

||

|

Thickness |

Nom. 1.4 mm |

|||

|

Armoring |

Copolymer coated corrugated steel tape |

|||

|

Ripcord |

2 opposite Ripcords under each jackets (totally 4) |

|||

|

Reinforcement |

None |

|||

|

Outer Sheath |

Material |

Polyethylene colored black |

||

|

Thickness |

Nom. 2 mm |

|||

|

Cable Diameter |

Nom. 16.5 …. 21.5 mm |

|||

|

Cable Weight |

Nom. 284 … 430 Kg/Km |

|||

PERFORMANCE:

|

Specification |

Recommended |

|||

|

Mechanical Characteristics |

||||

|

Tensile Strength |

2.7 KN |

|||

|

Min. Bending Radius |

Installation |

15*D (Cable Diameter) |

||

|

Operation |

20*D (Cable Diameter) |

|||

|

Environmental Characteristics |

||||

|

Temperature |

Installation |

-30°C to +70 °C |

||

|

Operation |

-40°C to +80 °C |

|||

|

Performance Test |

||||

|

Compression |

EIA/TIA 455-41-A |

Pulling |

IEC-794-1-E1 |

|

|

Water penetration |

FOTP-82 |

Kink |

IEC-794-1-E10 |

|

|

Cable Flexing |

EIA/TIA-455-104-A |

Twist |

EIA/TIA-455-85 |

|

|

Repeated Impact |

EIA/TIA-455-25-C |

Temperature Cycling |

IEC-794-1-F1 |

|

|

Low or high temperature bend |

EIA/TIA 455-37 |

|

|

|

Description